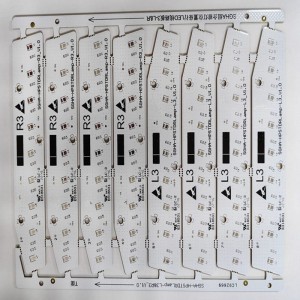

Quick turn pcb surface treatment HASL LF RoHS

Product Specification:

| Base Material: | FR4 TG140 |

| PCB Thickness: | 1.6+/-10%mm |

| Layer Count: | 2L |

| Copper Thickness: | 1/1 oz |

| Surface treatment: | HASL-LF |

| Solder mask: | White |

| Silkscreen: | Black |

| Special process : | Standard |

Application

The circuit board HASL process generally refers to the pad HASL process, which is to coat tin on the pad area on the surface of the circuit board. It can play the role of anti-corrosion and anti-oxidation, and can also increase the contact area between the pad and the soldered device, and improve the reliability of soldering. The specific process flow includes multiple steps such as cleaning, chemical deposition of tin, soaking, and rinsing. Then, in a process such as hot air soldering, it will react to form a bond between the tin and the splice device. Tin spraying on circuit boards is a commonly used process and is widely used in the electronics manufacturing industry.

Lead HASL and lead-free HASL are two surface treatment technologies that are mainly used to protect the metal components of circuit boards from corrosion and oxidation. Among them, the composition of lead HASL is composed of 63% tin and 37% lead, while lead-free HASL is composed of tin, copper and some other elements (such as silver, nickel, antimony, etc.). Compared with lead-based HASL, the difference between lead-free HASL is that it is more environmentally friendly, because lead is a harmful substance that endangers the environment and human health. In addition, due to the different elements contained in lead-free HASL, its soldering and electrical properties are slightly different, and it needs to be selected according to specific application requirements. Generally speaking, the cost of lead-free HASL is slightly higher than that of lead HASL, but its environmental protection and practicability are better, and it is favored by more and more users.

In order to comply with the RoHS directive, circuit board products need to meet the following conditions:

1. The content of lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE) should be less than the specified limit value.

2. The content of precious metals such as bismuth, silver, gold, palladium, and platinum should be within reasonable limits.

3. The halogen content should be less than the specified limit value, including chlorine (Cl), bromine (Br) and iodine (I).

4. The circuit board and its components should indicate the content and usage of relevant toxic and harmful substances. The above is one of the main conditions for circuit boards to comply with the RoHS directive, but the specific requirements need to be determined according to local regulations and standards.

FAQs

HASL or HAL (for hot air (solder) leveling) is a type of finish used on printed circuit boards (PCBs). The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Excess solder is removed by passing the PCB between hot air knives.

HASL (Standard): Typically Tin-Lead – HASL (Lead Free): Typically Tin-Copper, Tin-Copper-Nickel, or Tin-Copper-Nickel Germanium. Typical thickness: 1UM-5UM

It doesn't use Tin-Lead solder. Instead, Tin-Copper, Tin-Nickel or Tin-Copper-Nickel Germanium may be used. This makes Lead-Free HASL an economical and RoHS compliant choice.

Hot Air Surface Leveling(HASL) uses lead as part of its solder alloy, which is considered harmful to humans. However, Lead-free Hot Air Surface Leveling (LF-HASL) does not use lead as its solder alloy, making it safe for humans and the environment.

HASL is economical and widely available

It has excellent solderability and good shelf life.