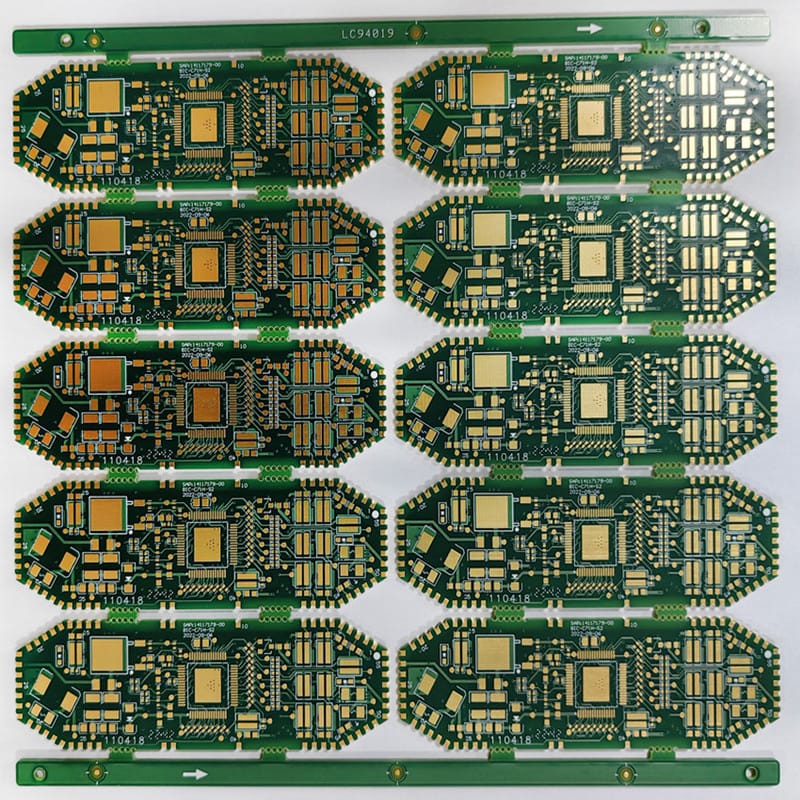

Pcb board prototype half holes ENIG surface TG150

Product Specification:

| Base Material: | FR4 TG150 |

| PCB Thickness: | 1.6+/-10%mm |

| Layer Count: | 4L |

| Copper Thickness: | 1/1/1/1 oz |

| Surface treatment: | ENIG 2U” |

| Solder mask: | Glossy green |

| Silkscreen: | White |

| Special process : | Pth half holes on edges |

Application

The TG value refers to the glass transition temperature (Tg), which is an important parameter for the thermal stability and heat resistance of PCB boards. PCB boards with different TG values have different properties and application scenarios. Here are some common differences:

1. The higher the Tg value, the better the high temperature resistance of the PCB board, which is suitable for application scenarios in high temperature environments, such as automotive electronics, industrial control and other fields.

2. The higher the Tg value, the better the mechanical properties of the PCB board, and the strength indicators such as bending, tensile, and shearing are better than those of the PCB board with a lower Tg value. It is suitable for precision instruments and equipment that require high stability.

3. The cost of PCB boards with lower Tg value is relatively lower, which is suitable for some application scenarios with lower performance requirements and stricter cost control, such as consumer electronics. In short, choosing a PCB board suitable for your own application scenario will help improve product quality and stability and reduce production costs.

4. The tg150 printed circuit board implies a circuit board developed with a tg150 board. TG often implies the glass transition temperature, which refers to the steady reversible change of amorphous material from a sturdy and “glassy” state to a rubbery and viscous state upon the application of higher than expected temperatures. While the TG often proves lower than the melting temperature of the corresponding crystalline material state.

5. The glass transitional temperature material often comes as a burn-resistant material, distorting/melting at specific temperature ranges. A tg150 PCB comes as medium TG material because it falls above the range of 130 degrees Celsius to 140 degrees Celsius yet below the 170 degree Celsius equivalent or higher. Please note that the higher the TG of a substrate (typically epoxy), the higher the stability of the printed circuit board.

FAQs

The heat required for the PREPREG rigidity must be applied without exceeding the FR4 Tg to preserve the PCB stability. The standard FR4 Tg is between 130 – 140°C, the median Tg is 150 °C and the high Tg is greater than 170°C

Standard Tg stays above 130℃ while high Tg above 170℃ and mid Tg above 150℃. When it comes to material for PCBs, high Tg should be picked, which should be higher than the working temperature current runs.

A tg150 PCB comes as medium TG material because it falls above the range of 130 degrees Celsius to 140 degrees Celsius yet below the 170 degree Celsius equivalent or higher. Please note that the higher the TG of a substrate (typically epoxy), the higher the stability of the printed circuit board.

The major factor to consider whether use 150 or 170 Tg PCB material is the working temperature. If it's less than 130C/140C, then Tg 150 material is okay for your PCB; but if working temperature is around 150C, then you have to choose 170 Tg.

A high Tg PCB contains a resin system that's designed to withstand lead-free soldering and enables higher mechanical strength in harsh, higher temperature environments. Resin refers to any solid or semisolid organic substance that's often used in plastics, varnishes, etc.