Shenzhen Lianchuang Electronics Co.,Ltd, a premier manufacturer of PCB products, is dedicated to the creation of top-tier circuit boards tailored to the requirements of diverse industries. Our factory boasts state-of-the-art production machinery, encompassing both semi-automatic and fully-automatic production lines. We adhere to a lean production management approach, ensuring rigorous quality control, prompt delivery, and stringent cost management.

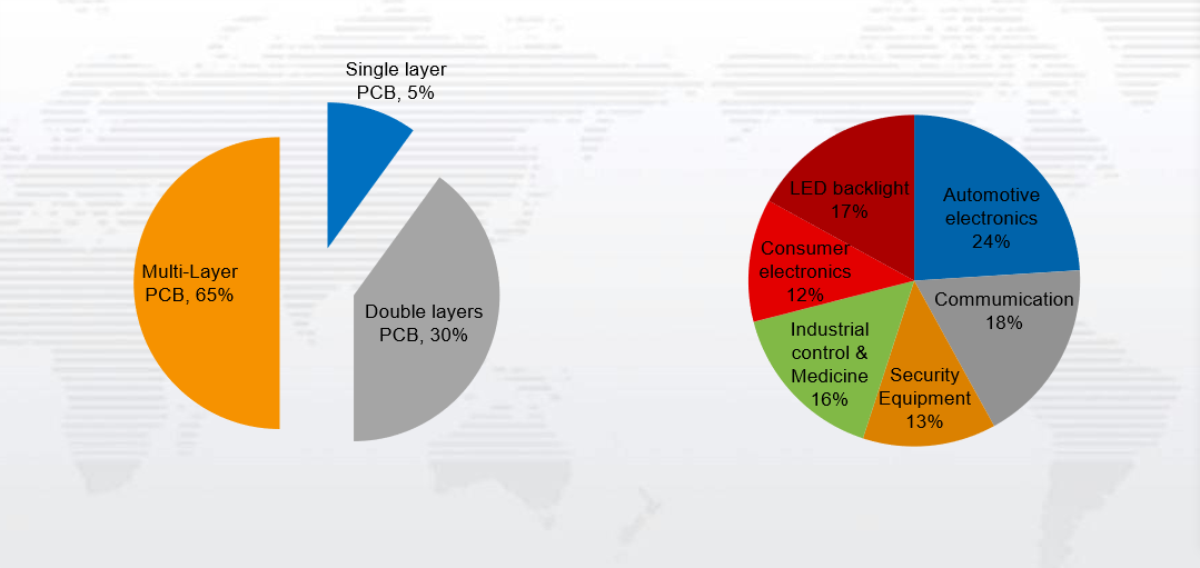

Our company is steadily progressing towards becoming a business specializing in high multi-layer, rapid prototyping, and small to medium batch production. Currently, multilayer boards constitute the majority of our product portfolio. Furthermore, we have consistently broadened and refined our product distribution over the years. Our products are now extensively utilized in a range of sectors including automotive electronics, industrial control modules and equipment, power supplies (such as charging stations for new energy vehicles), network communications, medical equipment, security, computer peripherals, LED lighting, TV backlighting, and consumer electronics. Our product quality has consistently received accolades from customers across these sectors.

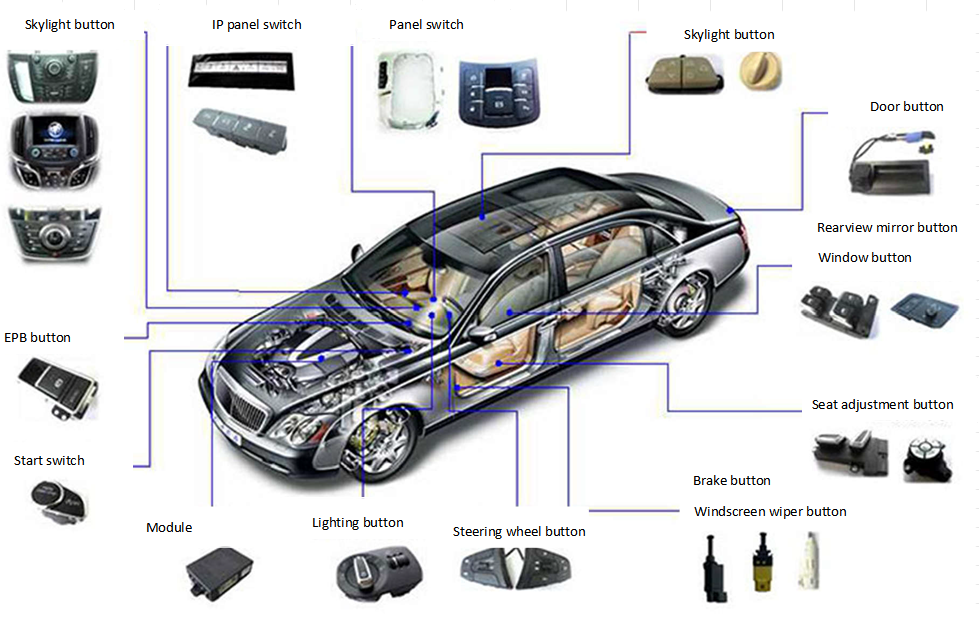

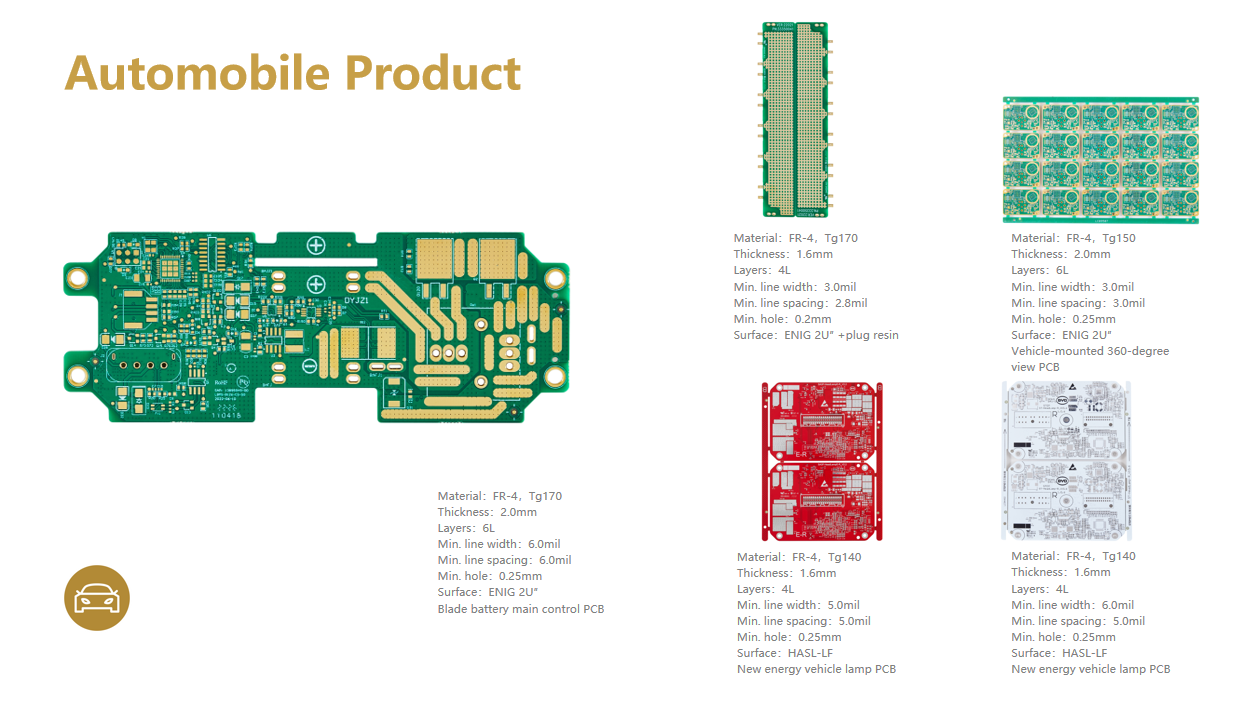

In line with the advancement of new energy vehicles, Shenzhen Lianchuang has established a substantial long-term partnership with BYD. Our focus lies in the fabrication of lightweight automotive components, incorporating circuit board products such as car light panels, automobile displays, vehicle speakers, and various car panel switch buttons. We intend to maximize our technological prowess and production capacity to cater to their escalating demands and provide crucial support for the intelligence and efficiency of automobiles. Simultaneously, we will capitalize on BYD's clout and resource benefits in the new energy vehicles realm to bolster our R&D and innovation capabilities in this sector, incessantly enhancing the technical sophistication and added value of our products, thereby offering our customers more competitive products and services.

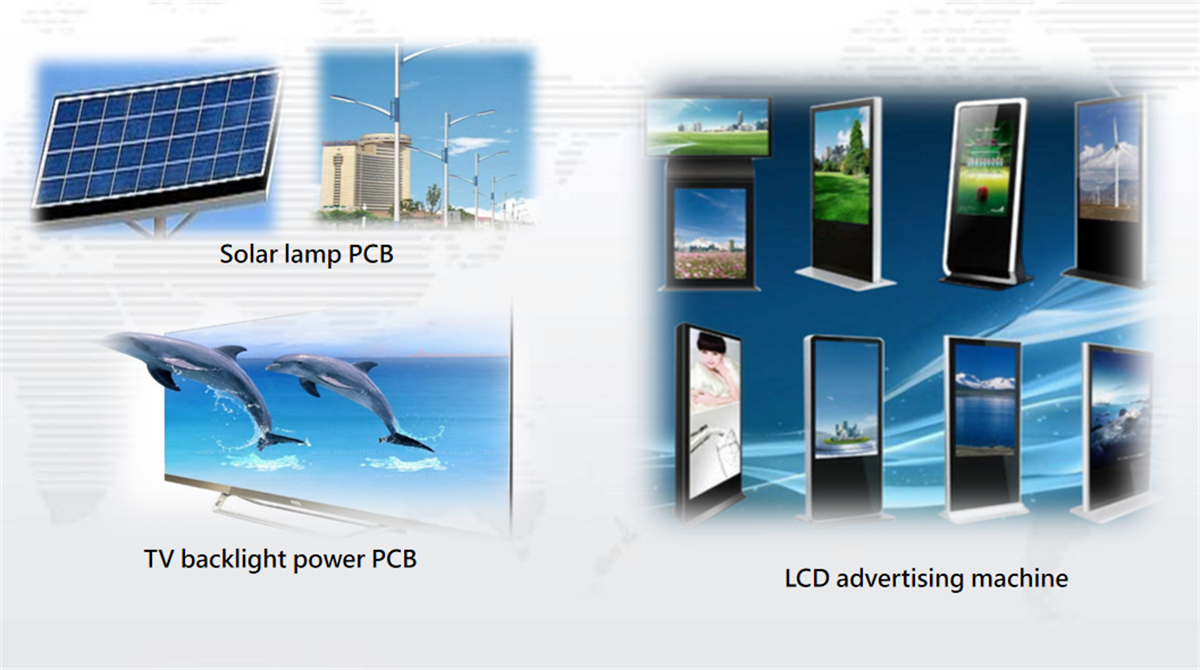

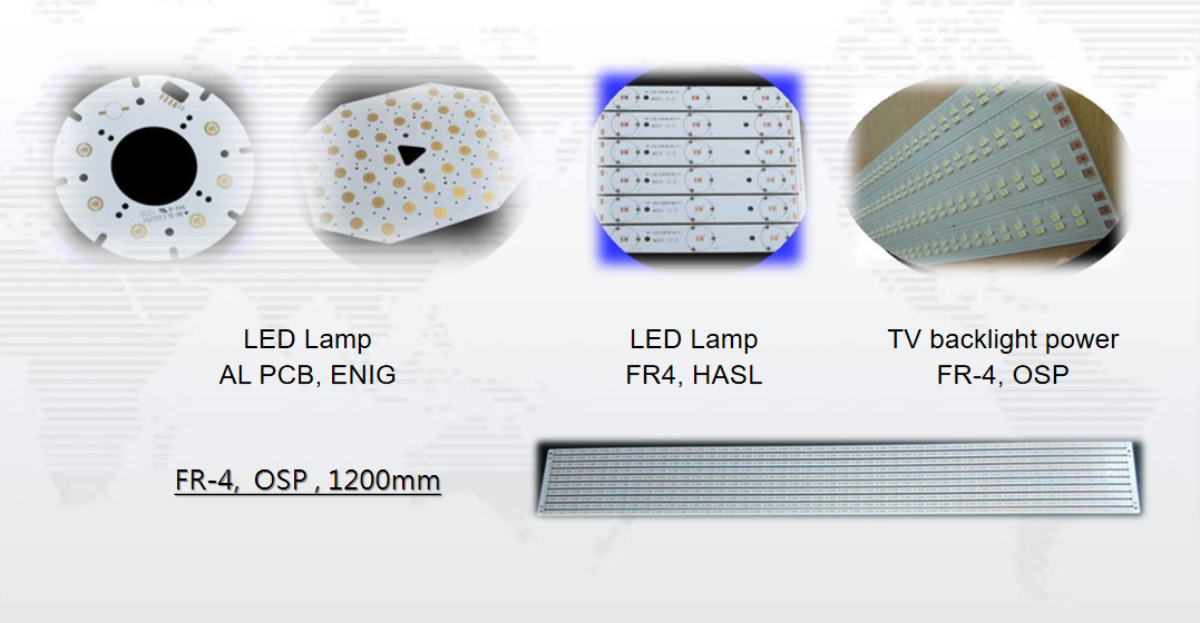

Furthermore, Shenzhen Lianchuang's PCB have found extensive applications in solar energy, LCD, and backlight power supplies.

Solar panels, being an eco-friendly electricity generation method, have gained increasing popularity in recent years. As the pivotal component of the solar power generation system, solar circuit panels serve a crucial role. Circuit boards can be employed for the connection and support structure of solar panels, as well as the circuit design and layout of solar control systems. Our solar PCB panels have been widely adopted in numerous areas such as home power generation and public building power generation, and the demand for orders has seen a surge in recent years.

LCD, or Liquid Crystal Display, is a form of flat panel display technology that leverages the unique physical, chemical, and optoelectronic properties of liquid crystal materials. It's presently the most mature and extensively used display device in flat panel display technology, predominantly used in televisions, monitors, laptops, tablets, smartphones, and other fields. The PCB board can be utilized to drive the circuits and interfaces of the LCD display, as well as control the LCD display's backlight. Regarding backlight power supply, PCB boards can be used to design and manufacture circuits and control systems for LED backlight modules.

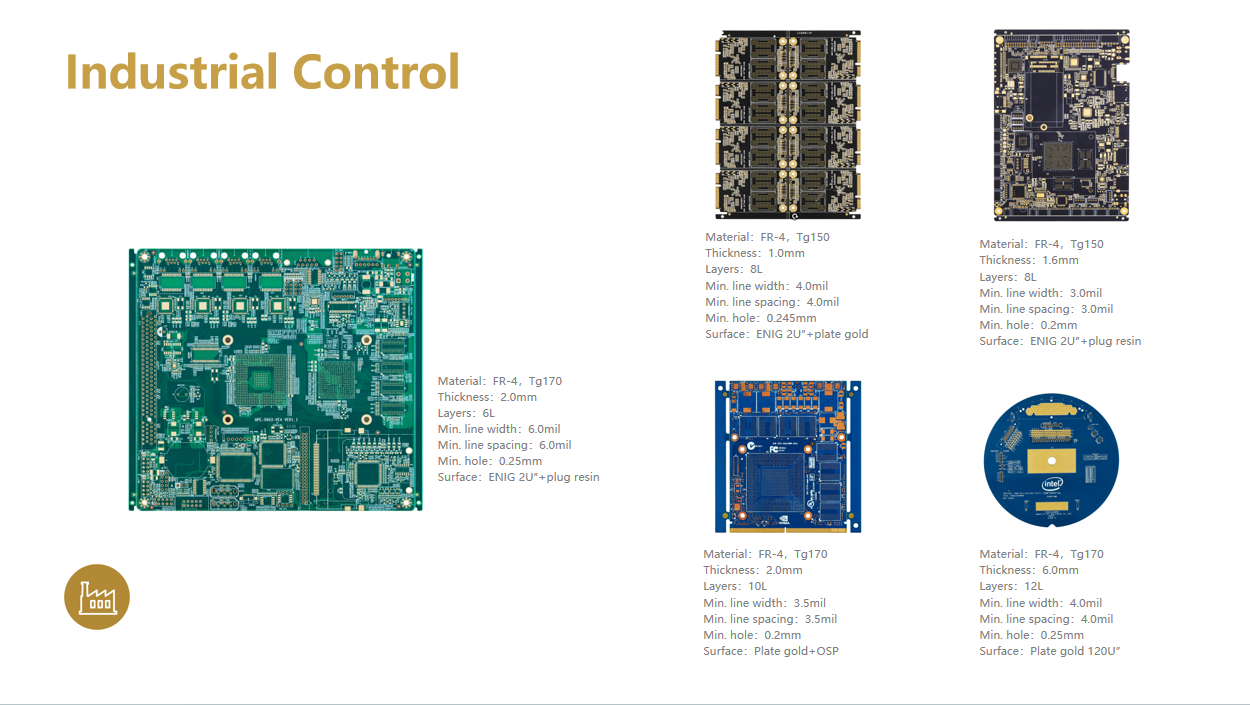

In the industrial control sector, circuit boards are a common component in industrial automation, robotic control, and automated manufacturing.

These industrial control circuit boards primarily employ integrated circuits and other electronic components to regulate industrial procedures and gather data. Their operating principle is to interact with external devices via input and output interfaces, and to conduct data processing and storage through processors and memory.

Industrial automation necessitates the use of numerous electronic components like sensors, actuators, and controllers, which need to be interconnected via circuit boards. These circuit boards serve to connect various sensors, actuators, and control chips, enabling automated control and monitoring. Stability, reliability, and anti-interference capabilities are crucial attributes for PCBs in this field. Industrial control circuit boards play a significant role in facilitating industrial automation, enhancing production efficiency and quality, and reducing labor costs and risks.

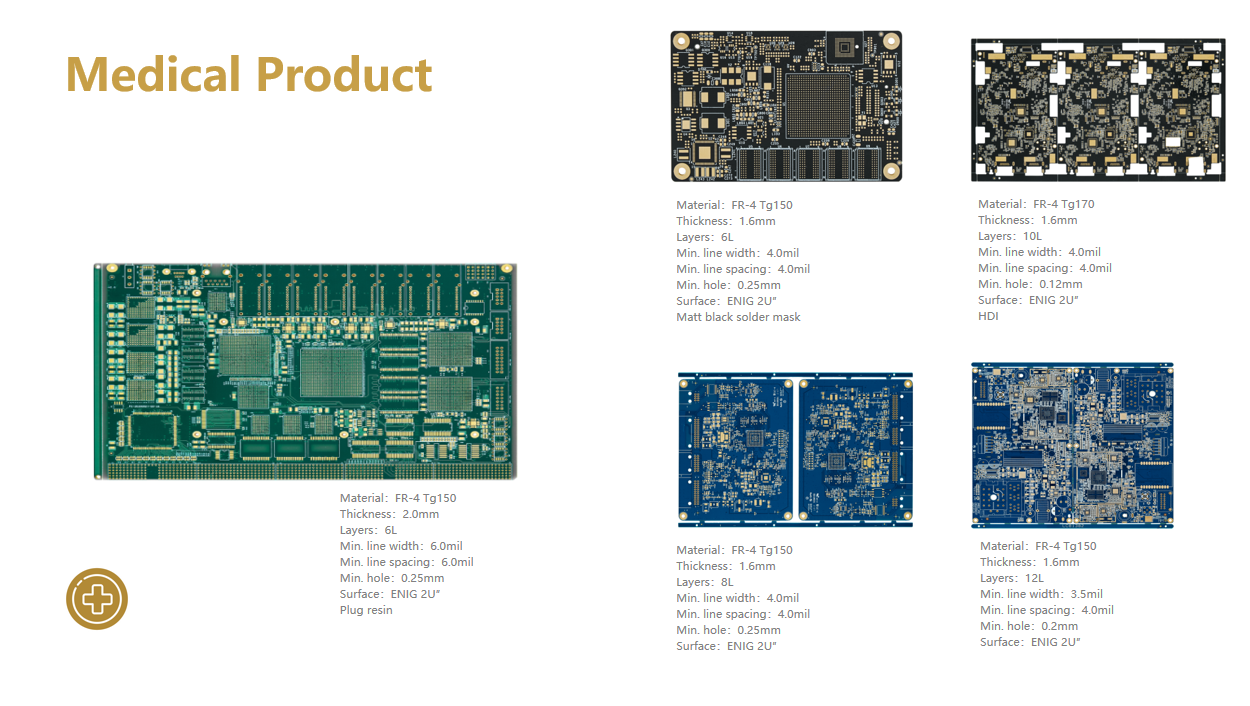

Shenzhen Lianchuang has acquired the ISO 13485 certification for medical device quality management systems and has been approved for the GJB 9001C weapons and equipment quality management system certification. With the ongoing advancement of medical technology in recent years, the use of medical PCB has broadened significantly. These circuit boards are incorporated in various medical devices, such as electrocardiographs, blood glucose meters, oximeters, etc. Medical information systems require an abundance of printed circuit boards to execute functions such as data collection, processing, storage, and transmission. This is evident in doctor workstations, medical record management systems, image processing systems, etc. Medical monitoring systems necessitate the real-time collection, processing, and transmission of data from various devices. PCBs are integral to achieving these functions, as seen in ventilator monitoring systems, vital signs monitoring systems, etc. The medical industry undeniably has stringent quality requirements for circuit boards. Products need to fulfill criteria such as accurate and stable data collection and transmission capabilities, equipment safety, long-term trouble-free usage, high reliability, and easy maintenance.

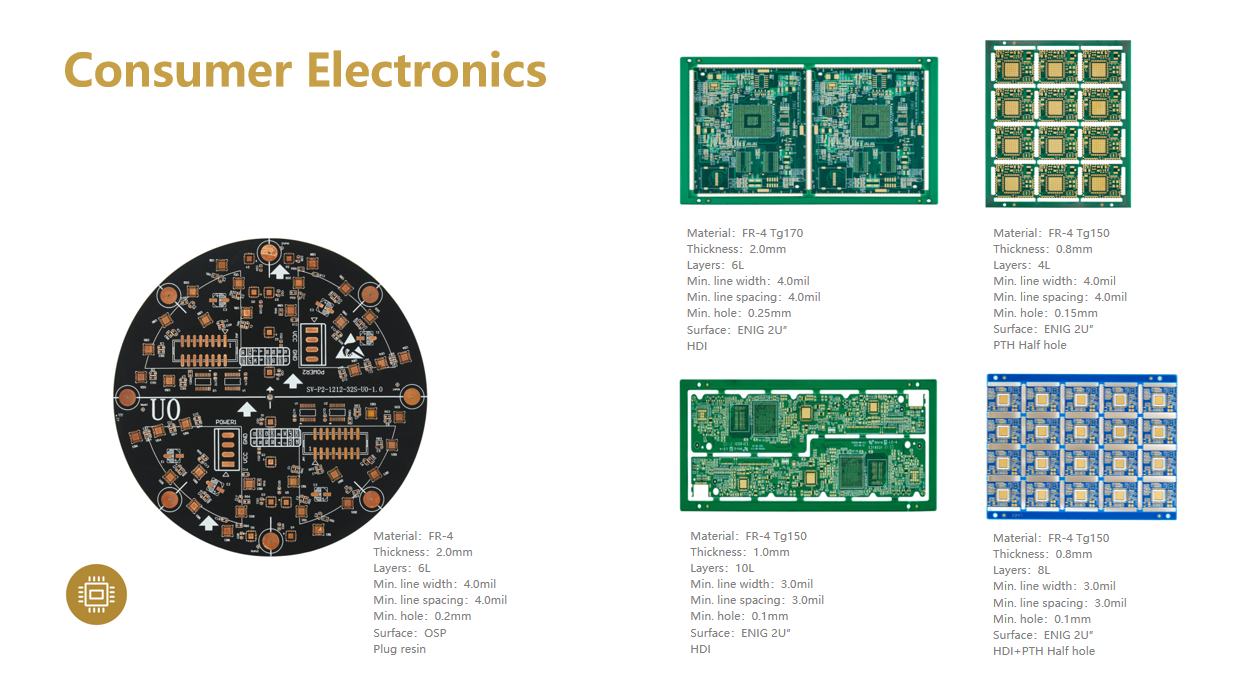

In the consumer electronics sector, circuit boards serve as the essential "brains" of various electronic devices, facilitating the connection and support of components like chips, sensors, and power supplies to enable diverse functions. As consumer electronic products undergo continuous enhancements, the demand for circuit boards is on the rise. In smart home systems, circuit boards are omnipresent, playing a vital role in systems ranging from smart lighting and security to smart temperature control. Each subsystem necessitates efficient and reliable circuit boards to ensure the seamless operation of its functions. For instance, in smart lighting systems, LED light panels utilize precise PCB design for light intensity adjustment and color changes. In the realm of smart security, PCBs are crucial in linking various sensors and cameras, ensuring swift response and data processing across the entire system. Smart wearable devices like smart watches and health monitoring bracelets impose elevated demands on PCB design, requiring not only a high level of integration but also adaptability to intricate ergonomic designs. For instance, PCBs in smart watches must integrate multiple sensors while remaining lightweight and durable. Leveraging advanced PCB technology, smart wearable devices can monitor users' health in real-time and offer personalized health insights through data analysis.

With the continuous march of technology, there is a strong belief that PCBs will persist in delivering their unique value in the domain of smart hardware, fostering the emergence of more innovative products and ushering in added convenience and delight into our lives.

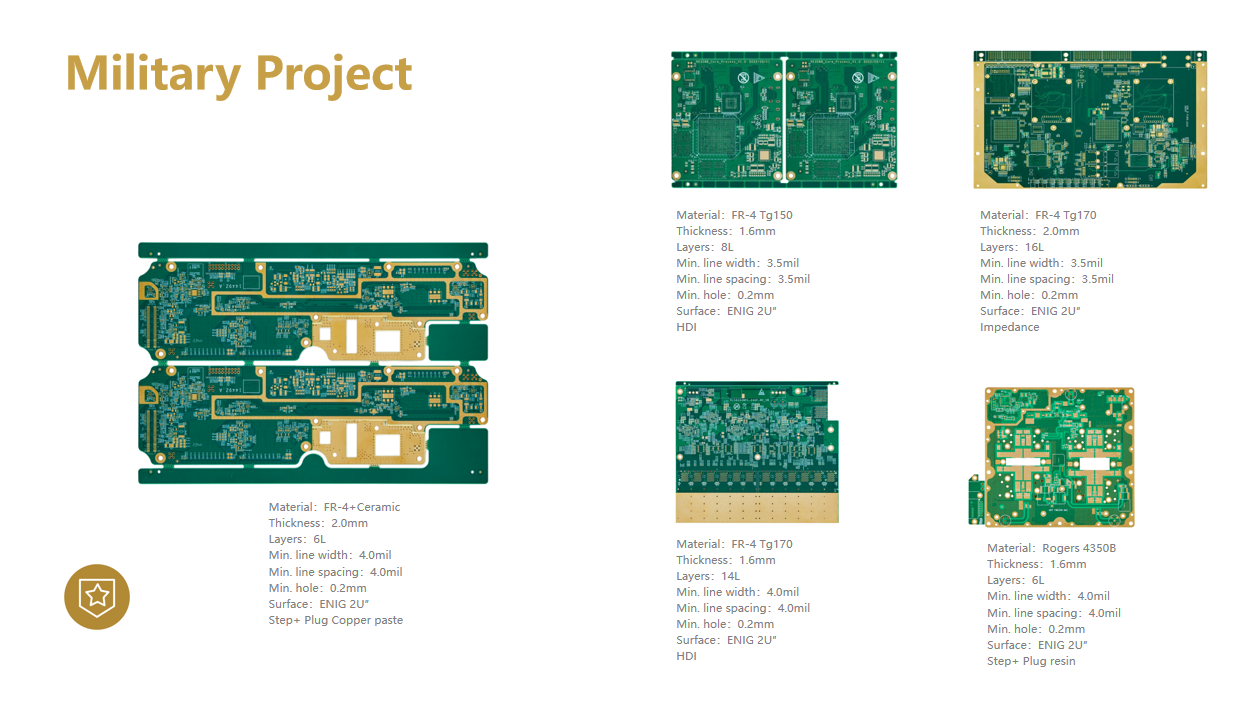

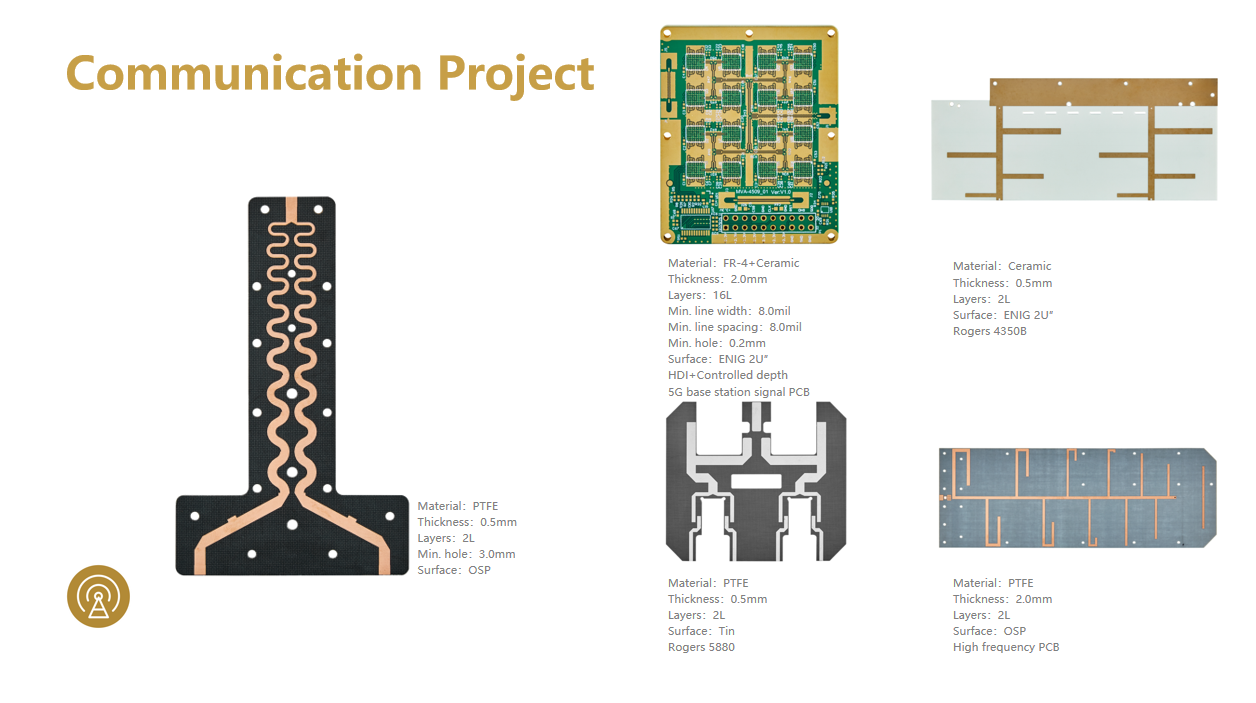

In the realm of communications and military, the requisites for PCBs typically encompass high-frequency characteristics, anti-interference capabilities, stability, among others. The evolution and adoption of 5G technology have propelled the demand for high-frequency and high-speed transmission, driving advancements in high-frequency materials and high-density PCB technology. High-frequency PCBs predominantly feature materials such as PTFE (polytetrafluoroethylene), FR-4 (glass fiber copper-clad laminate), Rogers, ceramic boards, etc. These materials are selected for their low dielectric constant, low loss, and suitability for high-frequency applications, commonly used in antennas, radio frequency, power, radar, 5G+ motherboards, and other products. The common high-frequency boards include RO4350B, RO4003C, among others.

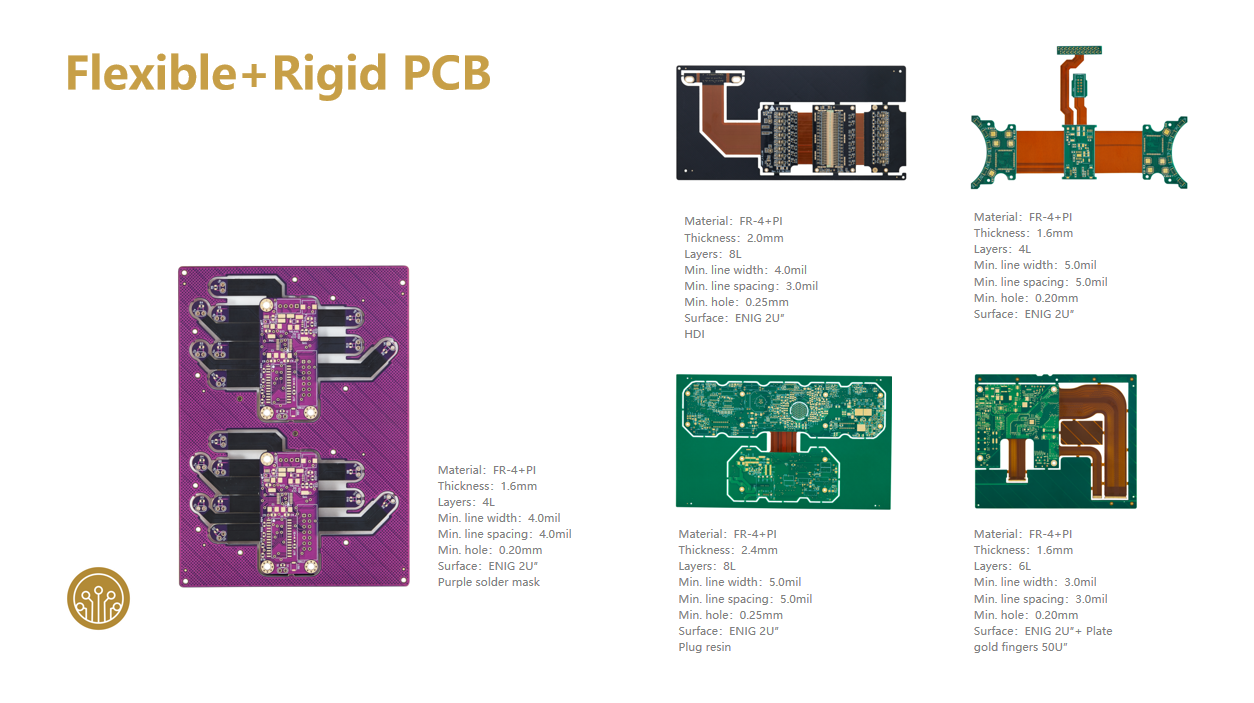

Rigid-flex boards combine the flexibility of a flexible circuit board with the rigidity of a standard circuit board, offering a blend of characteristics that support bending, folding, and rolling. This design enables lightweight, miniaturized, and thin solutions, facilitating the integration of component devices and wire connections.

FR4, a prevalent fiberglass laminate material, boasts high mechanical strength and thermal stability, making it a favored choice in PCB manufacturing.

PTFE boards, known for their excellent insulating properties, are ideal for high-frequency circuit design and find extensive application in microwave communications, aerospace, and related fields. These boards feature low dielectric constant, low dissipation factor, and exceptional chemical resistance. Additionally, there are ceramic-filled PTFE circuit materials like Rogers' RO3003, RO3006, RO3010, RO3035, and other high-frequency laminates.

Metal substrates, constructed with metal as the base material, offer excellent heat dissipation performance and mechanical strength, catering to the heat dissipation requirements of high-power electronic devices. Common metal substrates include aluminum substrates and copper substrates.